Description

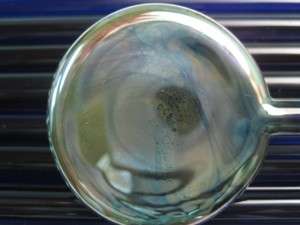

752.opl – An opal glass that strikes in the flame and kiln. Compared to the 740/743.opl it is slower striking, and more translucent after annealing. 752.opl can be worked hot and fast in the torch flame.

Working notes:

-To retain the transparent opal effect, limit kiln temperature and annealing time. I use 920F for up to two hours for misty-opal beads. Clear encasement seems to accelerate opacification in the annealer. Kilns vary in the amount of heat at the beads’ location vs the displayed temperature. Your kiln is probably different than mine. Test beads are recommended.

-A Reset/Cooling/Striking cycle can be used in the flame to alter the appearance of the opal effect. An encased bead that has been reset, air-cooled for 45 seconds, then very gently struck for 45 seconds seems to maintain the opalescent effect better than a bead annealed directing after resetting.

The 752.opl’s reset and striking temperatures are lower than that of silver glasses. When reset, the glass is crystal clear, and when fully struck the glass is a milky opaque white. Variable opacity can be produced by controlling the thermal history of the workpiece.

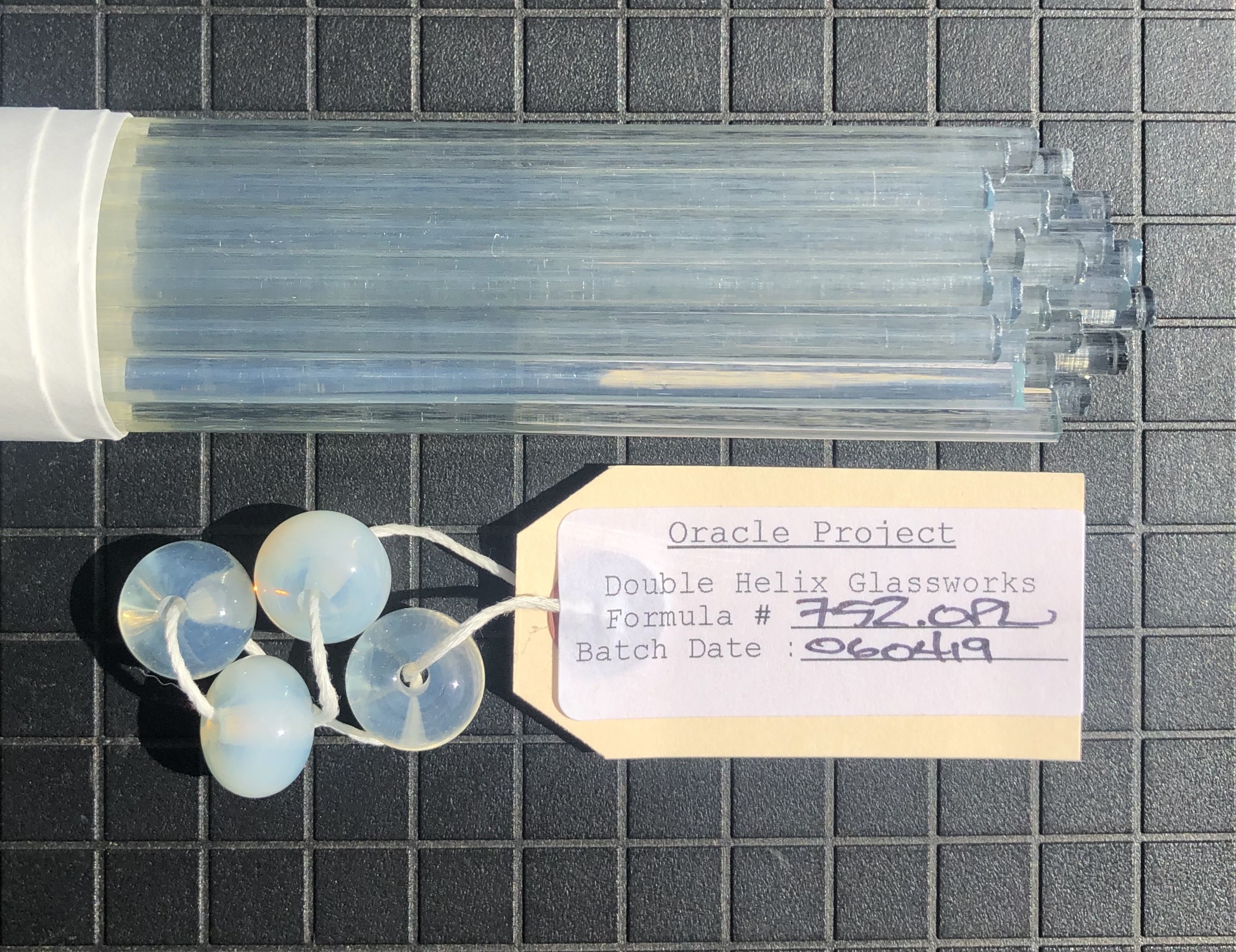

The Oracle Project – responsibly manufactured, low toxicity glasses made in the USA, without Antimony, Arsenic, Cadmium, Chromium, Lead, Nickel, or Selenium. Balancing viscosity curves, opacity, tonality, surface tension, and thermal shock resistance, to create glass that is a pleasure to work with in the flame.

The Oracle Project Test Batches – offered direct from the glassmaker to the artisan in small batches, sold by the pound, wrapped in paper. Labeled with batch date and formula number, with a suffix to indicate glass family type example, 740.opl

Reviews

There are no reviews yet.